The 'normal' polyurethane glues such as Elmers Probond and Gorilla Glue used to glue spars into EPS/EPP model aircraft are not available in Australia. This is the information concerning my attempts to find a suitable substitute in Australia. This information may be of assistance to other non-US modellers who need this type of glue.

There do not appear to be any obvious product on the shelves of hardware stores that are similar to the US glues. My initial researched uncovered two possible products. I contacted every mainstream glue supplier/manufacturer in Australia to enquire which of their products I should use. With one exception they had not heard of these glues and knew of no product in their range that would do what I wanted. I then contacted a number of specialist suppliers such as EPS/EPP carton manufactures and finally a specialised woodworking supplier.

The result of all this was two possible products:

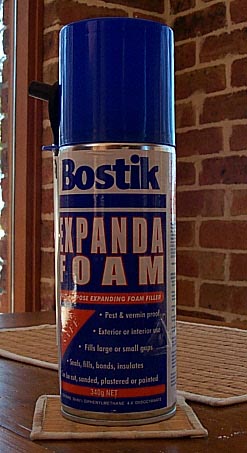

| The first possibility was a family of products in LPG propelled pressure cans. These products are sold as 'Polyurethane Gap Fillers' or similar. All claim to bond to a wide range of substrates, including EPS, and expand to about 200% of their initial size during curing. All are atmospheric moisture triggered one-part polyurethane. I purchased one as a sample, Bostik Expanda Foam. A detailed discussion with the manufacturer yielded the information that it would not 'bond' to polypropylene, however behaviour with EPP was uncertain. Typical cost for these products is A$7-9 per can. |

|

| The second possibility was a specialised woodworking glue AV515, manufactured by A.V. Syntec. This is an atmospheric moisture triggered one-part polyurethane glue, it is supplied in a 300ml cartridge. Cost for a cartridge of this glue is A$13. The manufactures information states the product is not suitable for Polypropylene. |

|

In order to determine if either of these products was suitable for installing spars in EPP models (such as the Bird Of Prey and Unicorn) I decided to test both of the two products I found. I did not test these products with EPS because of limited material and time.

The test I decided on was as follows:

The procedure went as follows:

| Step | Bostik Foam | AV515 |

|---|---|---|

|

Prepare sample foam blocks. Cut a spar channel and install sample spar. Top of spar 4mm below EPP foam, slot width about 6mm. Length of EPP foam 135mm |

|

|

| Weight of foam and spar | 8gms (+/- 2gms) | 8gms (+/- 2gms) |

| Notes regarding application of the glue. |

The applicator nozzle is 7mm in diameter and is difficult to get into the spar slot. Very difficult to get the foam to run under the tape, in the end I had to remove the tape and top fill. Foams very rapidly. |

The applicator nozzle is only about 4mm in diameter. It is still difficult to get the nozzle through the tape. It appears easier to remove the tape, apply the glue and then put tape back on top to get a smooth finish.Note that the AV515 will not set under tape. Foams very slowly, if at all. The glue is more like silicon sealer as it comes from the cartridge. |

| Appearance of the joint pre-cleanup |

|

|

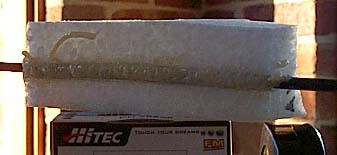

| Comments (after 6hrs) |

Appears stiff, almost no flexibility, like the inside of a Violet Crumble bar. However, the material is actually very flexible and very difficult to tear, break or pull apart. Bonds well to the spar and EPP Large air pockets in the material Material is fully set. |

Feels elastic and bouncy. Bonds well to spar and EPP Small pockets of air Material has not fully set. |

| Appearance after cleanup |

|

|

| Final weight of EPP block, spar and glue |

8gms (+/- 2gms) The scales appear unable to measure the increased weight with the foam. |

12gms (+/- 2gms) Feels heavier than the Bostik test block. |

| Comments after 24 hrs | Appears to have set completely, however, after the destruction test (below) it was clear that only about the outer 3mm of the glue had set. | |

|

Stress test A Attempt to push spar through the block and measure effort.

|

Took over 2.2 kg without any tear through. Put the spars end to end to try and see which glue gave way first - couldn't force either spar through! |

Took over 2.2 kg without any tear through. Put the spars end to end to try and see which glue gave way first - couldn't force either spar through! |

|

Test B Attempt to lift the spar out of the slot.

|

Took over 2.2kg at one end without any tear, at 2 kg the EPP started to deform as the spar tried to lift and the foam bonded to the spar refused to unbond from the EPP. The other end started to tear at 1.8kg with the bond to the EPP separating with a cleanish break leaving the EPP in original condition. (Ie. would be very easy to repair with no EPP damage.) When putting spar against spar to see which material separates first the Bostik Foam came away first. |

Unable to separate either end at 2.2kg. The bond to the EPP appears stronger than the Bostik Foam with no appearance of immanent separation. If sufficient force is applied it is possible to get the spar to rip out. When putting spar against spar to see which material separates first the Bostik Foam came away first. |

|

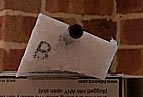

Destruction test. After ripping spar from foam. This is a view of the spar and foam after the spar was ripped out. |

The foam left attached to the spar was from a hard rip. The bond of the foam to the spar is not as good as AV515. It is possible to manually pull the foam from the spar. A combination of acetone and a knife removed all material from the spar. |

The bond of the glue to the spar is excellent, almost impossible to get off. Where the bond does come apart it is where the glue hasn't set yet. A combination of acetone and a knife removed all material from the spar. It took a lot more effort to remove the AV515 from the spar than the Bostik foam. |

The AV515 is a stronger glue, however this strength comes at the expends of weight and reduced gap filling properties. It is not clear whether the AV515 would eventually cure in the middle, and perhaps the glue is not really suitable for applications with large gaps. Increasing the moisture available with a water mister during the curing process may help.

The Bostik Foam is very strong for its weight and has excellent gap filling properties. It is a bit messy to apply and requires the removal of excess material after the foaming has stopped. However, given is weight (or lack thereof) it really is very strong.

I think that I will use the AV515 for applications where the volume of glue is small and there isn't much gap - eg. the spars on the Unicorn. Where the spars need to be glued into a channel routed into the wing the best option would appear to be to use a thin bed of AV515 to glue the spar in and then use the Bostik Foam to fill the remainder of the slot, or alternatively place a fillet of EPP on top of the AV515 to complete the channel.

The AV515 in the Unicorn spar slots worked perfectly.The glue was easy to get in with the nozzle on the cartridge and the slight foaming filled the cuts perfectly. The estimated weight of the AV515 required for the Unicorn was 34gms.

With the Bird Of Prey the bed of AV515 appears to have bonded well, and there is still a significant area that looks ideal for filling with the foam. The estimated weight of the AV515 required for the BOP was 36gms.